Nanotechnology & materials

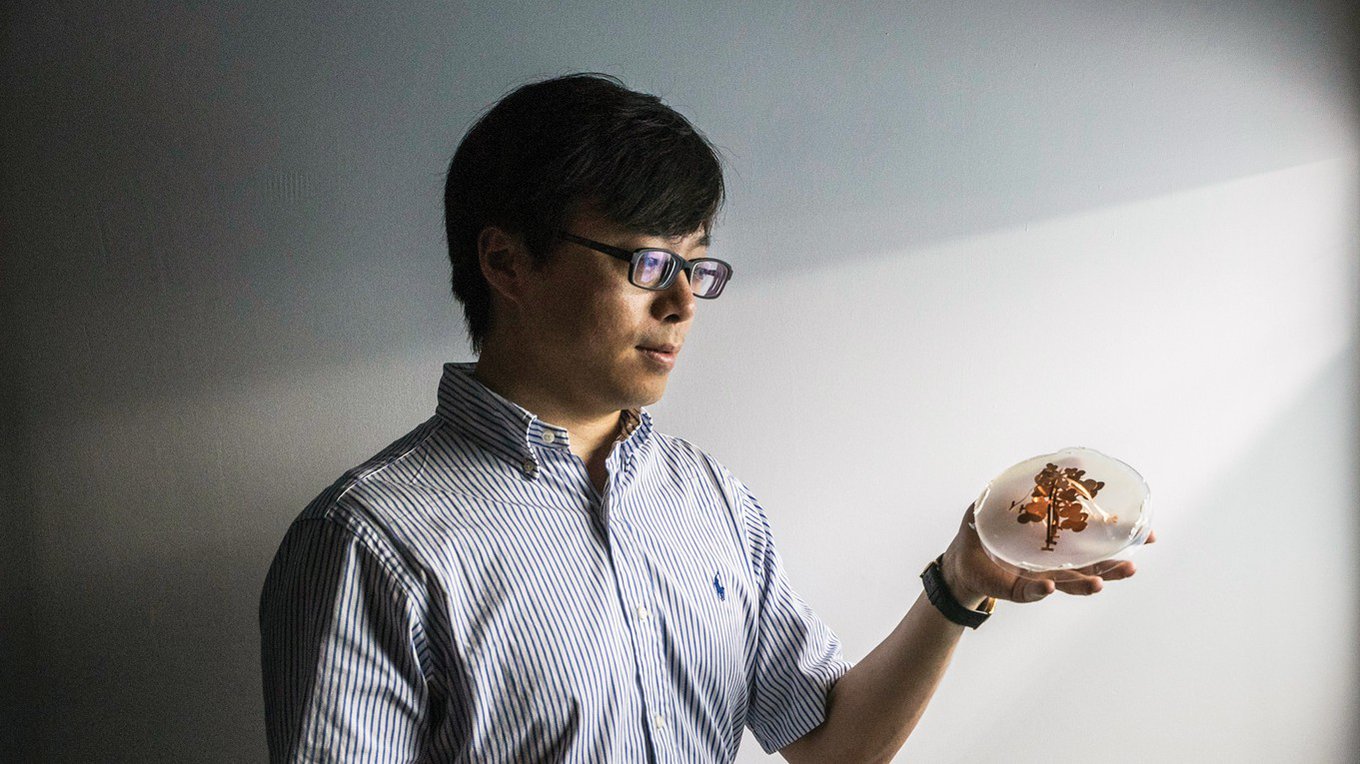

Yihui Zhang

Pop-up nanostructures make it far easier to fabricate very tiny shapes.

Photo by Gilles Sabrie

Europe

Timothée Boitouzet

Translucent wood: a resistant and sustainable material for constructing the buildings of the future

Asia Pacific

Madhu Bhaskaran

Transparent Wearable Devices

Europe

Bartłomiej Kołodziejczyk

His conductive polymers allow for the creation of biosensors and more affordable flexible solar panels

Europe

Grzegorz Wróblewski

Converts any surface into an electrode thanks to his transparent and flexible carbon nanotube coating