Energy & sustainability

Yanwei LUM

Revealed the catalyst mechanism to construct carbon-based materials from carbon dioxide and water.

Global

Richard Wang

Developed lithium-metal batteries, which have extremely high energy density.

Europe

William Brant

Co-founder of Altris AB

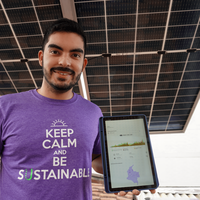

Latin America

Eduardo Ospina

Aims to democratize and decentralize clean energy by financing solar panel projects with the use of blockchain.

Asia Pacific

Jing MENG

She analyzed the costs of carbon-neutral technologies for better carbon policy-making.