"Imagining a swarm of drones hovering around a plane of passengers could generate more suspicion than calm among the potential occupiers of the aircraft. This fear is unfounded in the case of the UFOs created by Donecle, the French start up from Toulouse, which far from posing a threat, helps to guarantee security and save airlines hundreds of millions of euros.

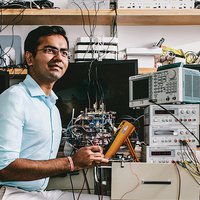

Matthieu Claybrough, the founder of Donecle, is one of the prize winners of Innovators under 35 France in 2016. His drones, with a wingspan of 80cm, 8 rotors and a weight of 4 kg, fly above the aircrafts located on the inside of the hangars, looking for damage on their surfaces. Through cameras and an advanced scanning software, they can detect defects in real time that are produced , for example, by the impact of lightning during the flight. It may seem a rare phenomenon but of the more than 27,000 active commercial planes, each one on average suffers from one lightning bolt every year.

With Donecle´s technology, a group of three drones and just one operator is sufficient to examine a narrow plane in 20 minutes. The apparatus of Donecle navigates autonomously – without the need of GPS or beacons – thanks to a system of Simultaneous Localization and Mapping (SLAM). “They carry laser sensors that acquire a group of 3D points which measure the distance from the drone to what can be viewed. They then process the information to estimate the position relative to the aircraft”, explains Claybrough.

SLAM has been known for some time, but Donecle wants to increase the autonomy and speed of its drones´ operations. Rather than starting from no base when mapping the environment, the drones carry a preloaded 3D image of the plane, and its software is trained to take advantage of the fact that it knows the model of the plane it is going to inspect in advance. “The process is much quicker and the estimation of the position can be executed by the drone autonomously”, points out Claybrough.

The types of inspections that can be carried out are also pre-programmed in the robot´s flying system so that the operator just needs to select the most appropriate option. The information that the images capture (position, defect size, logos or signs on the plane´s frame etc.) is also processed on board the drone. Via Wi-Fi, they only transmit relevant information that can save time in the post production, to the station on the ground.

Up until now, visual inspections have been carried out by 15 operators with hydraulic platforms and other heavy equipment. It takes them between 6 and 8 hours to complete a standard examination. Donecle can carry out the same inspection 20 times quicker. Claybrough´s drones could also be used to examine tunnels, wind turbines, bridges, boats and other large infrastructures where the process is slow and can be dangerous for operators.

For Matthieu Somekh, who is in charge of the Innovation and Entrepreneurial Initiative at the Ecole Polytechnique and is a judge for MIT Technology Review Innovators Under 35 France, this technology is “an important innovation that is growing quickly and is targeting a large market.”

The airlines are indeed forced to regularly inspect their aircrafts, especially if they have been exposed to forces like thunder or hale. Every hour one of these is inactive, when it is being examined for example, it means the airlines lose $10,000. A system like Donecle can carry out inspections more quickly and efficiently, and is therefore very promising."