Single-use plastics are becoming a serious threat to the planet, and there are already many initiatives to find both traditional substitutes (such as cloth bags or metal cutlery) as well as new ones. The price of production and the ease with which these alternatives can be manufactured are some of the challenges that the industry faces. Among the traditional materials that stand out for their resistance, durability and ease of recycling is glass, but in order to produce the purest fused silica, temperatures of around 2,000°C are required, as well as molds that can withstand that heat. This increases the price of products made with it.

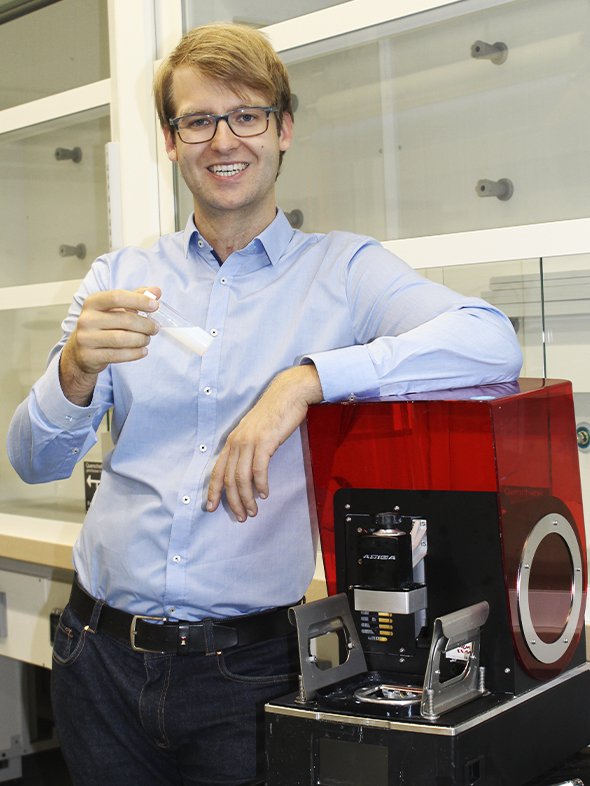

To solve this problem, the German Frederik Kotz has developed a nanomaterial that could become a cheaper version of glass. During his doctoral studies, the young man invented compounds that simplify the structure of glass and make it as malleable as clay. It takes advantage of polymer techniques already applied in 3D printers to simplify and reduce the cost of a century-old manufacturing process. Thanks to this work, Kotz has become one of the winners of Innovators Under 35 Europe from MIT Technology Review.

The nanomaterial has been baptized as glassomer, as has the company that develops it and of which Kotz is Co-founder and CSO. It consists of a solid or liquid compound based on fused silica, an amorphous quartz used for centuries in industry and research whose use stands out in optics and photonics. Among its properties, glassomer is unique for being as transparent and resistant as traditional fused silica glass and with an imperceptible roughness of just a few nanometers.

In order to achieve these characteristics, it is only necessary to heat it up at around 1,300°C, which allows energy to be saved in the process. All this makes it indistinguishable from commercial glass, but cheaper. Kotz formulated the material so that it would also be possible to make glass of various thicknesses without decomposition, as well as being practical enough to work with using anything from a knife to polymer processing techniques, such as those of a 3D printer.

The Glassomer team is already collaborating with a 3D printing company to produce 50-micron microlenses. When inserted into an optical fiber, these microlenses can be used in surgeries and endoscopies. Kotz believes that micro-optics is one of the fields that can benefit most from his technology, along with glass bottles, as it is a material that can be colored and recycled more easily than plastic. The young man explains, "We can adjust the material properties of these crystals very easily."

Alex Kingsbury, a Metal Additive Specialist at Additive Economics and a member of the Innovators Under 35 Europe 2019 jury, says that the material "will be useful in many sectors, particularly the very relevant ones such as telecommunications, electronics, and medicine." In addition, he highlights Kotz's "significant research effort" to make glassomer work.

By José Manuel Blanco

Translation: Brian Bostwick