Computer & electronics hardware

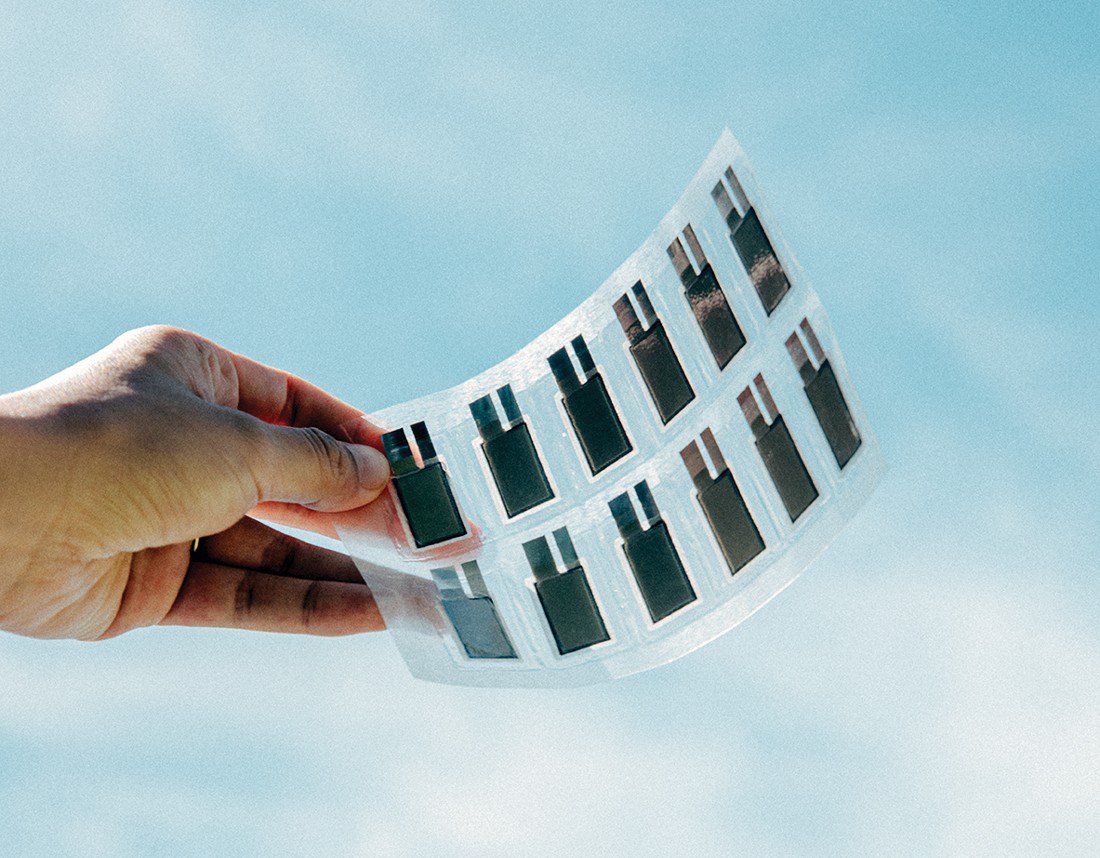

Christine Ho

Her startup is commercializing thin, flexible, printable batteries that she developed at UC Berkeley.

Photos by Timothy O’Connell

Europe

Petros Psyllos

His wearable tech allows the blind to interpret their surroundings through audio messages

Global

Alex Hegyi

A new type of camera could let smartphones find counterfeit drugs or spot the ripest peach.

Europe

Luis Cuende

Using Bitcoin technology as a notary public 2.0 and to fight patent trolls

Europe

Matthieu Claybrough

His crowd of drones identifies problems on the surface of a plane in just 20 minutes